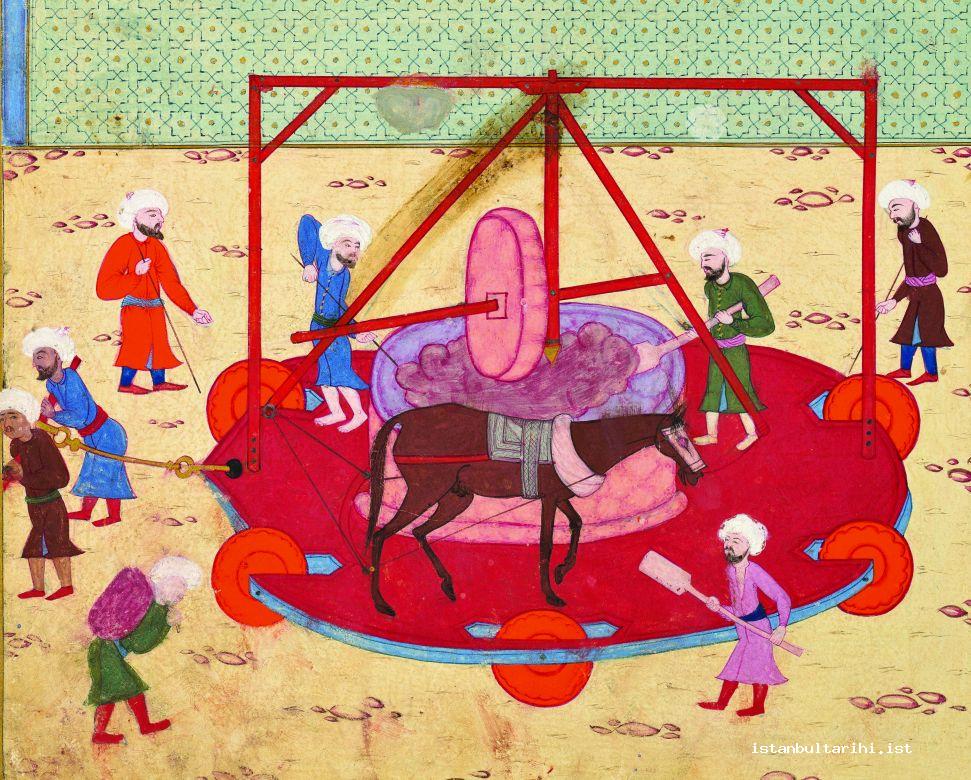

There were three types of mills until the mid-nineteenth century in the Ottoman state: 1) Windmills that were used in windy regions and were driven by wind force; 2) Watermills that were generally set in places rich in streams and were driven by water force; and 3) Mills that were driven by animal force. In Istanbul, the mills driven by animal force were predominantly used. While in some regions of the Ottoman territory, oxen were used in order to rotate the millstones, in Istanbul horses were preferred. Although horse-driven mills were costlier than others, it had its own advantages. First, horse-driven mills were more stable and they can be easily set in preferred places and regions.

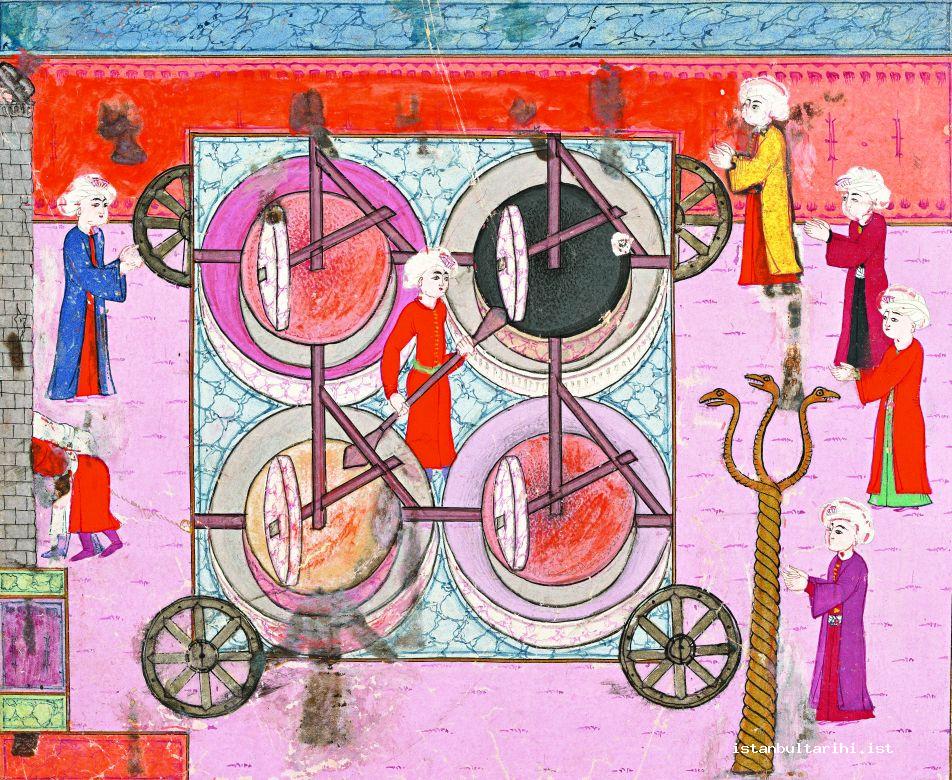

As for every Ottoman tradesman, millers had their own regulations among them. In accordance with these regulations, issues such as how many horses would rotate each millstone or in what size the grindstones would be were all predetermined. Hence a grindstone was rotated by four horses in the mills of Istanbul according to these regulations. Furthermore, no miller had a right to say “I can do it with three horses.” The grindstones were called either “horos” or “çarh” (Wheel) according to their size. The “horos” stones were 8 spans in width and 8 fingers in thickness. From the late eighteenth century the number of “çarh” stones decreased, while “horos” stones came to be more preferred.

For the millers of Istanbul, every detail of their job was minutely regulated and recorded, ranging from where the grindstones that were going to be used in the mills would be brought from, which neighbourhood the fodder of the horses would be provided from to which field or garden the manure of the horses should be delivered. For instance, millers could not bring their grindstones from anywhere except for Foça and the fodder required for the horses workings in the mills were brought from the farms around Istanbul, mostly from Büyükçekmece and Küçükçekmece. The size of the mills was determined according to their grindstones. The more grindstones they had, the bigger they were deemed. One “çarh” (wheel) stone was equal to two “horos” stones and the millers who want to change their “çarh” stones with “horos” stones could take two “horos” stones in exchange for one “çarh” stone. In an undated document, it was stated that a pair of horos stones cost 22 kurus and a pair of çarh stones cost 24 kuruş. Furthermore, according to a 1797 dated document, these prices were 24 and 38 kuruş respectively. In 1806, owing to the price increase in iron, steel, gunpowder, coal, labour force and transportation, it was requested that the prices of a pair of horos and çarh stones would be marked up to 30 and 50 kuruş respectively.

By the regulations of the millers, they did not have the right to increase the number of their mills or millstones at will. But when needed, they could obtain the opportunity to increase the number of their millstones by courtesy of the qadı (judge) and the kethüda (the deputy of the governor). Nevertheless, if the millers had valid reason, they had the right to transfer their grindstones to other mills. As a matter of fact, if a miller could not afford to rebuild his mill which was burned in a broken out fire, according to the regulations, he could transfer his grindstone(s) to another mill. For this reason, when the millers wanted to add new millstones to their mills, they had to buy the idle ones first. Yet the millstones inside the walled city in Istanbul could not be moved outside the walled city.

Partner’s interests were determined according to the number of horses in the mills. In many documents, we encounter phrases as “I have the possession of twenty-five horses and “şayi” share (i.e. booked and nonshared share), valued at 6.5 horses, consisting of certain obligatory equipment, which are called “gedik”1 among tradesmen” If a miller had a disagreement with his partner about accounts, he would apply to the Ministry of Cereals for the settlement of it. On the application the minister of cereals would set up a commission gathering the supervisor of the grains, chieftan of the millers, the regulations master and competent tradersman together to re-examine the accounts and settle the disagreement.

The cereals required for the mills of Istanbul were provided from Unkapanı (The Flour-market) and the storehouses of shipyards. While Unkapanı represented the private enterprise, the storehouses of shipyards represented the state. When the private sector could not meet the needs of the millers, the state would immediately step in and distribute the grains stocked in storehouses for the millers. Although, according to the regulations the millers had to have their own storehouses and to have in their stock the amount of cereals adequate for six months, some millers did not conform to this obligation.

The state took every measure to prevent any problems that would result in famine or scarcity. The subsistence of the capital city was deemed a state policy. Each miller had an officer called kapancı who was responsible for the cereals that would be bought from the storehouses. In the mills that were operated on partnership, this officer was generally chosen among the partners. Although in the mills only wheat was grinded, in cases of famine, the millers were allowed to grind barley and corn as well. But when not necessary, the millers were forbidden to grind barley and corn. Furthermore, flour was imported from outside of Istanbul only when needed. If not necessary, flour import was not authorized at all. During military expeditions, the flour needed by the military was occasionally met from Istanbul. In that case, the cereal sent to the millers from the storehouses of shipyards was grinded in the mills for a fee. For instance, in the year 1799, 33.333 bushels of wheat were taken from the storehouses and were given to the millers of Istanbul to be grinded for 18 mites for each bushel. The cereal grinded at the mills was pro rata reduced by wastage. For example, when 33.333 bushels of wheat were grinded, 28.660 bushels of flour were obtained in 1799. Thus 14% of the wheat was wasted.

If any of the millers ran away or died when in debt, his mill would be sold to a Muslim if he himself was a Muslim and to a non-Muslim if he himself was a non-Muslim. Furthermore, the income of this sale was paid to the state and storehouse traders as debt allowance. In such sales, the state gave the millers the opportunity to pay their debt by instalments.

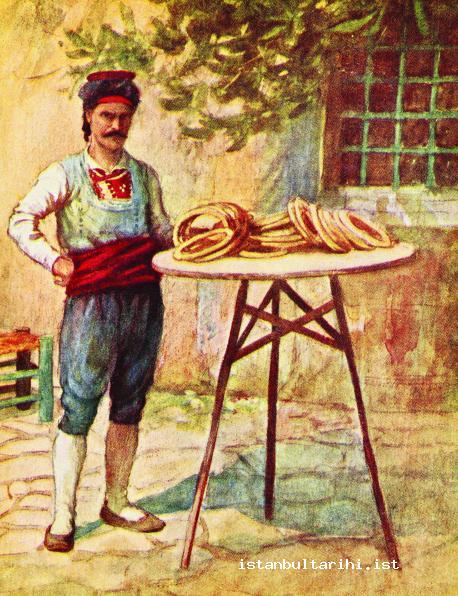

There were two types of mills in Istanbul: First type was the flour mills, which provided flour for bagel, kadayıf and lokma producers as well as to bread bakeries, and sold flour on their own counters. The second type was the bread makers’ mills which produced flour either for their own bakeries or for other bakeries they had to give bouche. The flour mills produced fine flour, while bread maker’s mills produced standard flour. The flour mills sold the whole wheat flour called the “black bagel” (kara simit) remaining after the production of fine flour in the mills, in markets to cameleers, villagers and sailors as fodder to their animals and whole wheat flour sale to bakeries was prohibited.

Bakery owners in Istanbul were encouraged to open a mill besides their bakery. Thus many bakery owners had their own mills. The bakers who did not have a mill of their own were obliged to buy flour from mills determined according to the regulations. Hence, these bakers could not be provided their flour except from determined mills.

Among the Ottoman tradesmen there was the system of batch production. For this reason the production amount of each mill was determined, and the mills were allocated cereal according to the numbers and size of the grindstones they had. For instance, the bread maker’s mills were given 20 bushels (512 kg) of wheat for each “çarh” (wheel) stone and 9 bushels (230, 4 kg) for each “horos” stone. Yet the grindstones of some mills were at times allocated to imarets for flour provision. In such allotments share for each “horos” was raised to 10 bushels. As for the flour mills that produced fine flour, the cereal amount for each “horos” was 8 bushels (200, 8 kg). In short, allocation was one bushel less than that of the bread maker’s mills.

In Istanbul the state at times took the inventory of the mills. The purpose of these inventories was to specify which mills gave how much flour to which bakeries and to determine which millers secretly added extra millstones to their mills, by comparison of the inventories to the registers of the millers’ chieftain. Thanks to the records of these inventories, we know the number of the mills in Istanbul and the cereal amount allocated to these mills. According to these records, in Istanbul and Bilad-ı Selase (Galata, Eyüp and Üsküdar) there were 231 bread maker’s mills in 1739. Furthermore, the number of grindstones in these mills was 991. In the year 1763 the number of mills reached up to 233 and that of the grindstones up to 1.118 with an increase of 127 stones. The average number of grindstones in the bread maker’s mills in the walled city of Istanbul was 5.2. In the year 1739, there were 116 flour mills in Istanbul and Bilad-ı Selase, the number of their grindstones being 360. According to the 1763 dated inventory, while there was no increase in the number of flour mills, there occurred an increase of 22 in their grindstone number and the average number of grindstones in flour mills was 3.3 for the same year.

The large part of the mills in Istanbul were bread maker’s mills. Their number of grindstones was almost three times more than that of the flour mills. When needed, the grindstones of flour mills could be transported to the bread maker’s mills by courtesy of the qadı and the kethüda. Neverheless, these transports were officialised and were recorded by the Chief Finance Secretariat.

Bread maker’s mill owners who bought grindstones from flour millers acquired the right use those grindstones for producing fine flour and selling it to bagel and pastry producers. For this reason, some grindstones in those mills were used to produce fine flour, while others for producing Standard flour.

Consequently, as we have stated above, the millers of Istanbul made production according to a well-defined and well-organized system. They did not have the opportunity either to make production or sale under the conditions of free competition, digressing from the regulations they were subjected towards. First, there was a certain auto-control among these producers and tradesmen and in addition to this, there was the state units’ tight control over their field of production.

BIBLIOGRAPHY

Aynural, Salih, İstanbul Değirmenleri ve Fırınları (1740-1840), Istanbul: Tarih Vakfı Yurt Yayınları, 2001.

Güçer, Lütfi, “XVIII. Yüzyıl Ortalarında İstanbul’un İaşesi İçin Lüzumlu Hububatın Temini Meselesi”, IFM, 1949-50, vol. 11, no. 1-4 (1949-50), pp. 397-416.

Güran, Tevfik, 19. Yüzyıl Osmanlı Tarımı, Istanbul: Eren Yayıncılık, 1998.

FOOTNOTE

1 For the term “Gedik” see DİA, XIII, 541; the term specifically signifies permanent right of disposition of those who hired waqf goods over those goods in return for the extra reparations and the equipment added onto those goods. The aforementioned goods is the grounds of this right of disposition called gedik.