The Ottoman State was established and began to expand in a period in which firearms were transforming the world. As a result, the future of the Ottoman State was directly related to the possession and utilization of firearms. The Ottoman army, which used firearms from the 1380s onwards, also produced weapons and ammunitions it needed. It was possible to come across a military factory in almost every province of the country. The same was the case for gunpowder; the government owned dozens of production facilities, for example, those in Gallipoli, Thessaloniki, Egypt and Buda. However, the most important production facilities were in Istanbul. Some of the gunpowder production facilities, which had been established immediately after the conquest of Istanbul, continued to operate until the era of the Turkish Republic. Aside from small-scale production facilities, large facilities were also established in Istanbul, such as those in Atmeydanı, Okmeydanı, Kâğıthane, Şehremini, Bakırköy and Azadlu; this produced gunpowder to meet the demands of the country.

The Atmeydanı Gunpowder Factory

The Atmeydanı gunpowder factory was the first gunpowder factory in Istanbul; it was either taken over from the Byzantine Empire immediately after the conquest of the city, or established in Istanbul around that time. The Güngörmez Church, located near Atmeydanı (the Hippodrome), in an old Byzantine building next to the Güngörmez Tekke, was used as a gunpowder factory. However, it is not clear whether or not the gunpowder was produced inside the factory, or if it was produced elsewhere and was stored here. During a fierce storm, lightning struck the gunpowder factory in 895 /1489-1490; in the resulting fire, not only did the building burn down, but many people died; four neighborhoods in the vicinity were also devastated. In the second volume of his book Hadîkatü’l-cevâmi, Hüseyin Ayvansarayi tells the story of how parts of the gunpowder factory fell around a mosque during the explosion; as a result this mosque became known as Kabataş (rough/coarse stones) Mosque.1 At the beginning of the 1570s, having been reconstructed, the gunpowder factory was able to produce 150 kantar2 (8 tons 461 kilograms) a month.3 Evliya Çelebi mentions that this factory existed while he was alive, and refers to it as the Janissary gunpowder factory, recording that there were five employees and one master.4 However, because it was inside the city, in due time, the factory was shut down.

The Okmeydanı Gunpowder Factory

Information about the Okmeydanı Gunpowder factory is quite limited. When the existing information is analysed, it can be understood that the order to establish the factory was given on 18 February, 1578. In a decree sent to the Janissary agha, Mustafa, the bölükbaşı of the Topçu Ocağı (cannoneers battalion) was ordered to construct a gunpowder factory at Okmeydanı, where the Janissary barracks were located. Eleven soldiers were appointed to work with Mustafa. The register of the factory was recorded separately, but inspections were to be carried out by the janissaries. According to the order, Mustafa had to produce 1.5 kantar (84.5 kg.) of gunpowder, and 400 grenades.5 After remaining in operation for 17 years, the gunpowder factory was destroyed in an accident that took place on January 20, 1595. A fire broke out in the late afternoon, and some of the workers died; as the fire broke out during the day, it was possible to extinguish it before it had a chance to spread to other buildings. Sources, however, do not provide any information in regards to what happened to the factory after the explosion.6

The Kâğıthane Gunpowder Factory

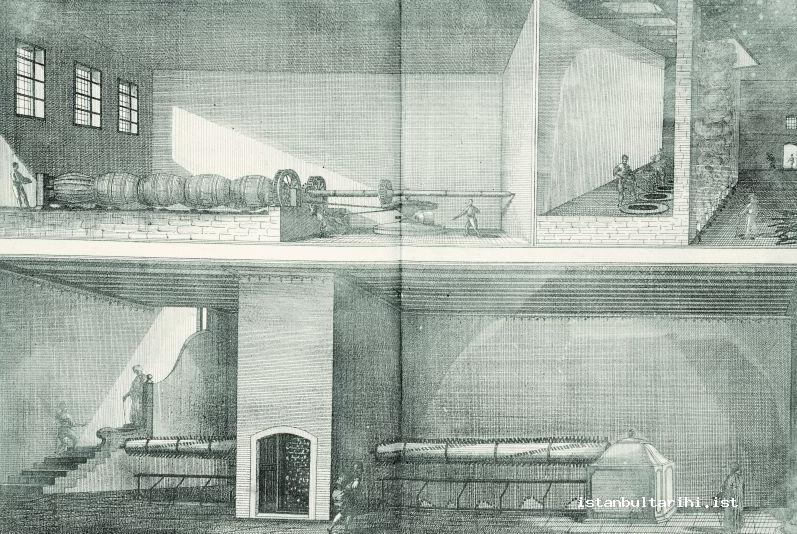

The Kâğıthane gunpowder factory was constructed as a wooden building by Sultan Bayezid II in the 1490s. It was reconstructed in brick, with a lead roof, by Süleyman the Magnificent. The mills of the gunpowder factory were operated with water from a nearby stream. As was the case in other gunpowder facilities, the one in Kâğıthane was also frequently restored or renewed. It is recorded that the building was rebuilt in 1570. Following the renovations, 300 kantar (16 tons 922 kg) of gunpowder began to be produced every month.7 According to the information provided by Evliya Çelebi, a gunpowder master from the Cebehane Barracks, a kethüda and 200 workers were appointed to the factory. There were 100 bronze mortars, each weighing 10 kantar (564 kg.) at the gunpowder factory. The cogs turned thanks to the waterwheels that were located on the Kâğıthane Creek. Evliya Çelebi explains how difficult the production of gunpowder was in his own entertaining style:

This was a dangerous place; if iron struck the mortar fire would start and all the workers would be blown into the air like phoenixes. There was nothing good to watch there. The noise from all the cogs and rods striking made a sound like thunder and lightning, making one’s brain shake.8

In February, 1638, 20 kantar (1 ton 128 kg) of gunpowder caught fire; the ensuing explosion tore the roof of the factory off.9 It is written in some sources that the Kâğıthane gunpowder factory continued to operate until the end of the Sultan İbrahim (1640-1648) era.10 However, recent research has discovered records that indicate 6,275.27 kantar (353 tons 975.5 kg) of gunpowder was produced here between 1683-1685,11 thus establishing that the gunpowder factory continued production until the end of the seventeenth century.12

The Şehremini Gunpowder Factory

In 1099/1687-1688, during the last years of the reign of Sultan Mehmed IV, the gunpowder factories in Gallipoli, Thessaloniki and İzmir were not able to meet the demand for gunpowder; as a result a factory was established near the Şehremaneti Market.13 With the Kâğıthane factory, this factory produced 3,000 kantar (169 tons 225 kg) of gunpowder was produced annually.14 In September, 1698, the cogs over-heated, and 310 kantar (17 tons 386.5kg) of gunpowder caught fire, causing a fire to break out; seven workers lost their lives in the fire, and twenty mill horses died. 425 houses in the Ördek Kasap, Müneccim Sa‘dî, Deniz Abdal and Saraç Doğan neighbourhoods were destroyed by the explosion. The glass in the windows of tall buildings, the most important of which were the Fatih Mosque and the Beyhan Sultan palaces, were broken. After this accident, the gunpowder factory was moved to Bakırköy.15

The Bakırköy Gunpowder Factory (Istanbul Gunpowder Factory)

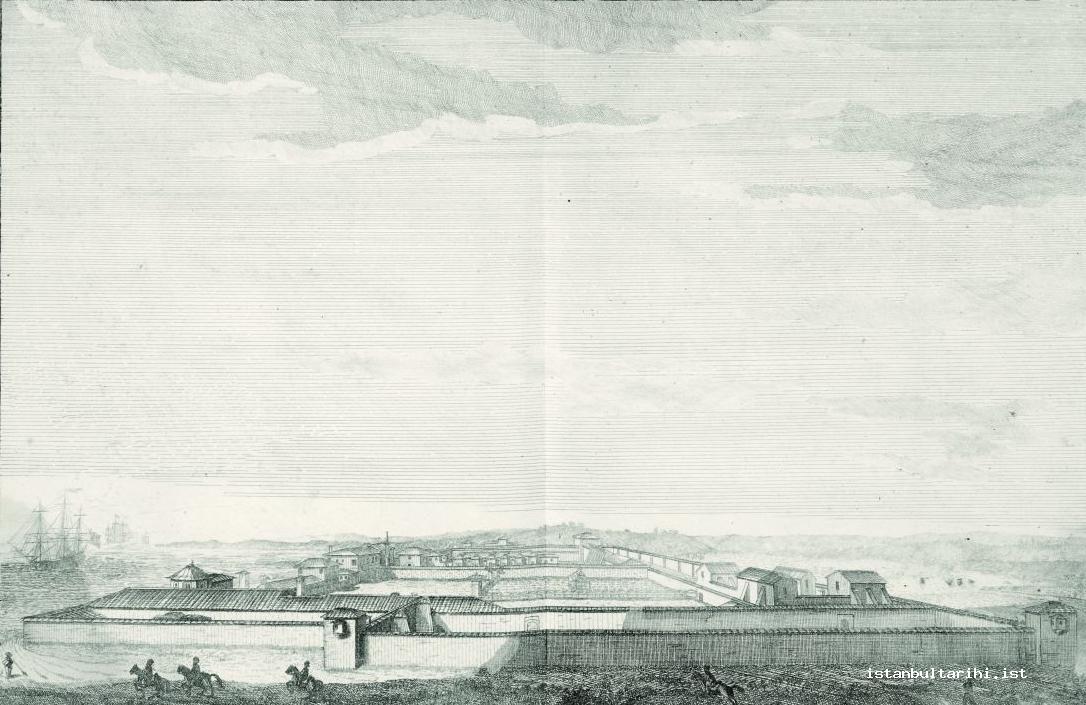

The Bakırköy gunpowder factory is recorded in official government sources as the “Baruthâne-i Âmire” (chief gunpowder factory). However, this was not the only name by which the factory was referred to: it was also commonly called the Bakırköy gunpowder factory, the Istanbul gunpowder factory or the Âsitâne-i Saadet.

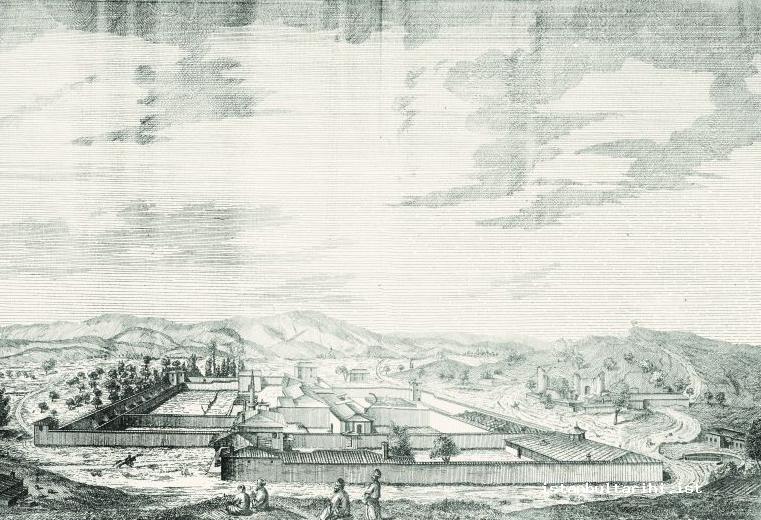

Because the explosion at the Şehremini gunpowder factory caused such tremendous damage in the vicinity, the factory was moved to a location outside the city. The new factory was established in a place known as İskender Çelebi Gardens, located near Yedikule; there were no residential areas close to this location. In May, 1698, the master gardener, chief architect, chief gunpowder officer and other experts began working on the construction of the factory. As a result of the initial survey, it was calculated that the factory would cost 29,684,100 akçe to build. However, because winter was approaching, construction did not begin, although the necessary material for construction had already been obtained. As the estimated costs were too high, the head architect Hüseyin Agha conducted a new survey at the beginning of 1700, and determined that the gunpowder factory could be constructed for 17,000 esedi kuruş. A portion of the necessary funds was allocated from the Maraş treasury, a portion from the government treasury, and the remaining portion was obtained from the Gümüşhane muqata’a (tax office).16 After this last survey, the construction of the gunpowder factory started and the factory began production in 1701.

On August 22, 1707, a short while after the Bakırköy gunpowder factory began production, a major accident occurred. As a result of the fire, all the buildings that made up the factory were destroyed, with eight workers losing their lives.17 The gunpowder factory was quickly rebuilt; in 1725, while the factory was still operating, another fire broke out. The walls of the factory were destroyed during the fire, and six cogs were burnt. Because the wooden cogs were constantly causing problems and being damaged even in the smallest fires, the new cogs were made of marble. With the renovation, a factory with 18 cogs and 12 millstones for each cog, amounting to a total of 216 millstones, was established. The renovation took a while and the factory was only able to begin operating once again in 1727.18 In the following years however, explosions and fires could not be prevented. As a result of the fire caused by an explosion in 1765, 166 kantar (9,363 kg) of gunpowder19 caught fire; the building was damaged, requiring a new large-scale renovation to be initiated.20 In 1785 however, comprehensive renovation and expansion efforts took place. The guard towers, sheds, smelter, gunpowder depot, perdahthane (grinding centre), 18 cogs and the office of the chief gunpowder officer were renovated.21 A fire broke out once again in 1791; this time, the interior minister, Ahmed Agha, had the destroyed parts of the building renovated.22

Towards the end of the eighteenth century, due to the lack of guidelines and a falling-off in the quality of the gunpowder, new regulations were introduced. On May 6, 1793, the Ministry of Gunpowder Factories was established and all factories were placed under its supervision.23 Mahmut Râif Efendi describes the changes as follows:24

After the Russian War, which began in 1768, the gunpowder produced in the three aforementioned gunpowder factories (Istanbul, Thessaloniki and Gallipoli) was mud-like in appearance. It was only used at festivals and it was necessary to purchase gunpowder for battles from abroad at 60-70 kuruş per kantar. A portion of the gunpowder purchased would be of good quality, however, most of it would be unusable; moreover, it was not always possible to purchase the gunpowder at the exact moment it was needed. Gunpowder is the main material for battles, indeed, the soul of warfare, and one cannot fight without it! This complacency and dependency on others for gunpowder became intolerable for Selim III. The first thing that was done to rectify this situation was to prevent the Ministry of Gunpowder Factories from being used like a rotating service, and as a result, these places stopped being places used by people for a term of a year to service for their pockets. A minister from among the leading government officials was appointed to oversee the factories.

Mehmed Şerif Efendi, one of the gunpowder factory ministers, first had the buildings, which were now in ruins, renovated, had new cogs constructed, and ensured an increase in the quality and amount of gunpowder that was produced.25 The renovation efforts of Mehmed Şerif Efendi, however, proved to be insufficient, and Mehmed Ragıb Efendi, who was appointed a short while after Mehmed Şerif Efendi, also implemented large-scale renovation efforts. New fortifications, citadels, a barracks for the Cebeci Corps and other barracks were constructed to ensure the functioning of the gunpowder factory.26

The factory operated every day except for Fridays. However, when an order for an amount of gunpowder was received that was above the capacity of the factory, permission would be obtained, and the factory could operate every day of the week. For instance, in 1199/1784-1785 the factory was operated on Fridays.27 Another issue of debate was the personnel employed at the factory. Even though it was recorded that 366 workers were at the gunpowder factory and salaries were paid for this number of workers, there was never this much personnel working at the factory. The annual production at the factory throughout the 18th century varied from between 1,500 and 3,000 kantar (approximately 84.5-169 tons). However, a constant topic of debate was not the amount produced, but rather the quality of the gunpowder produced. Gunpowder of the desired quality was never produced at the Bakırköy gunpowder factory. The use of horse power to turning the cogs both reduced the quality of the gunpowder as well as increasing production costs.28 It was for this reason that when the Azadlu gunpowder factory was being established, care was given to locate it near a place where the cogs could be turned by water.

The gunpowder factories were reorganized in 1835; the Ministry of Gunpowder Factories was abolished, and the factories were placed under the jurisdiction of the Ministry of Defence. Emin Efendi, who was the Minister of Military Munitions at the time, was summoned to the Sublime Porte and was informed of the situation.29 The gunpowder factories accountant (ruznamçeci), Salih Efendi was appointed as manager of the facilities.30

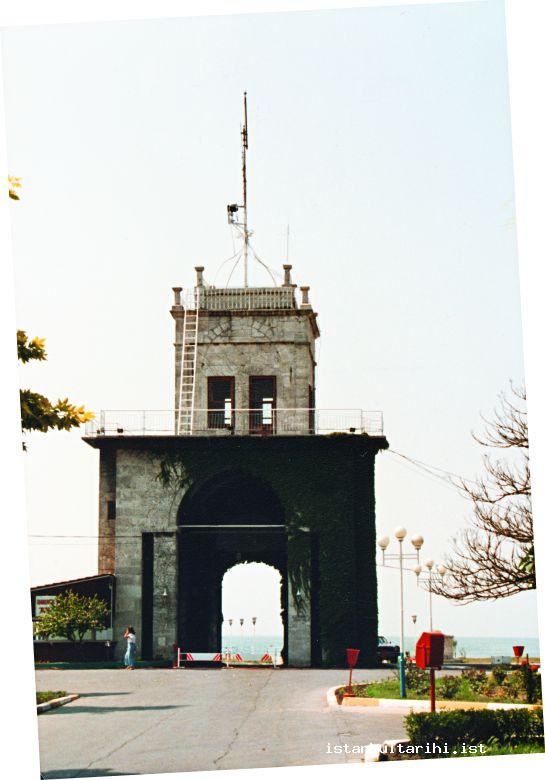

After the Tanzimat, new sections were added to the gunpowder factory, and it was put under the jurisdiction of the Tophane Field Marshall. During the Crimean War the equipment of the factory wore out, as the factory worked day and night to meet the increasing gunpowder demand; as a result, five modern mortar machines were purchased from England. Certain changes were made throughout the 19th century, in line with developments in gunpowder technology. In particular, after the 1880s, German technology began to be used.31 The factory was handed over to the military facilities administration during the Turkish Republic, and from here, it was transferred to the machine and chemical industries institution. The gunpowder factory, which preserved its military identity until 1953, became unusable in the same year after a fire.32 The premises, which measured 4.000.000 m2, were sold to the Turkish Emlak ve Kredi Bank for 60.000.000 lira in 1955. On September 15, 1957, the construction of the Ataköy apartment complexes began on the plot of land where the factory had stood.33 The main building of the factory however, after remaining abandoned for some time, was given a basic renovation and used as a discotheque, called the Barut Fıçısı (Gunpowder Barrel), operated by the Ataköy touristic facilities management.34 Following this, the gunpowder factory building, which had been left to decay, was opened for service on March 3, 1993 as the Yunus Emre Cultural Center. To create this cultural center, the Bakırköy Municipality spent two years in renovating the buildings.35 The clock tower located inside the Ataköy Marina was one of the towers of the gunpowder factory and still stands tall today. 36

The Azadlu Gunpowder Factory

One of the innovations implemented during the era of Selim III was the establishment of the Azadlu gunpowder factory. Work begun in 1794 to establish a factory along the Azadlu Stream, thus enabling quality gunpowder to be produced with new equipment ordered from Europe; in addition, this location was outside the city. Selim III considered the Azadlu gunpowder factory to be one of the most important components of the Nizam-i Cedid movement. For this reason, he frequently visited the factory, both during the construction phase and afterwards.37 Mahmud Raif Efendi, one of the important names in the Nizam-i Cedid movement, argued that the establishment of the Azadlu Factory was a well-advised decision. He explains why a new gunpowder factory was necessary in the following sentences:

Because the Istanbul gunpowder factory did not have a stream running next to it, the cogs were turned by horse power. However, by using water to turn the wheels, the gaps in the cog are struck at an equal rate and the raw material will be ground finer. Consequently, compared to the cogs that were turned by animal power and which could not strike the gaps at an even pace, and thus, were unable to grind the raw material evenly, these wheels produce better quality gunpowder. When this issue was understood, the construction of a new gunpowder factory and brick pools began in this location, as there was a river near the Azadlu Village close to Küçük Çekmece.38

The construction of the factory was completed in 1796 with the efforts of Mehmed Şerif Efendi. As a result, a gunpowder factory that operated with quite new and modern methods, using water power, had been established. When the Azadlu gunpowder factory began to operate, the Thessalonica39 and Gallipoli40 facilities were shut down, and their revenues were transferred to the Azadlu factory.

With the Azadlu factory, the quality of the gunpowder produced equalled that of the English gunpowder and 10,000 kantar (564 tons) were produced annually. As Mahmud Raif stated: “Not only was the possibility of experiencing difficulties eliminated; like European countries, (we) began to sell the product to Islamic countries and others who were in need.”41 However, even though a certain standard of quality was attained, contrary to what Mahmud Raif wrote, the desired amount of gunpowder could not be produced here, and it was never exported. That the goal was to produce gunpowder equivalent to the quality of the English and Dutch product can be understood by the frequent warnings that were given.42

Like the Bakırköy factory, constant renovation took place at the Azadlu gunpowder factory as well. The first large scale renovation took place in 1819. In 1839 however, the factory was equipped with the latest technology from England. Heavy metal beams, weighing one hundred okka, were positioned to open the pumps that had been brought from London, chutes and chimneys were constructed to provide ventilation for the salt-peter (potassium nitrate) solution.43 A broadcloth factory was added to the Azadlu gunpowder factory in 1804. To enter production, the broadcloth factory requested a total 700 kantar (39 tons 485.5 kg) of wool from the districts of Çatalca, Silivri, Küçük Çekmece and Mihaliç.44 The factory however, was unable to function and ended up being abandoned.45 When Russians invaded the area during the wars of 1877-1878, the gunpowder factory was damaged and the production activities came to an end. During the years of the second Meşrutiyet, the buildings of the gunpowder factory and the surrounding area were given under the ownership of Resneli Niyazi family, who was one of the pioneers of Meşrutiyet movement and until 1950’, it was called as the Farm of Resneliler. In 1952, the farm was shared between the heirs. During the World War II, 20. Topçu Alayı was temporarily settled in Azadlu Gunpowder factory and for the accommodation of the soldiers new buildings were constructed.

Abandoned pools, retaining walls, two wheels, and two large marble millstones for grinding gunpowder are all that remain from the gunpowder factory today.46 These remnants were left to the interest of amateur treasure hunters for many years; in recent times, as a result of articles in various newspapers, this structure has attracted the attention of the Ministry of Culture and attempts have been made to preserve it.47

FOOTNOTES

1 Semavi Eyice, “Baruthâne”, DİA, vol. 5, p. 95.

2 1 kantar equals 56,408 kg.

3 Gábor Ágoston, Barut, Top ve Tüfek: Osmanlı İmparatorluğu’nun Askeri Gücü ve Silah Sanayisi, tr. Tanju Akad, Istanbul: Kitap Yayınevi, 2006, p. 175.

4 Evliya Çelebi, Seyâhatnâme, Istanbul İkdam Matbaası, 1341, vol. 1, p. 560.

5 Ahmed Refik, 10. Asr-ı Hicrîde İstanbul Hayatı, Ankara: Kültür ve Turizm Bakanlığı, 1987, pp. 170-171; İsmail Hakkı Uzunçarşılı, Osmanlı Devleti Teşkilâtından Kapıkulu Ocakları, Ankara: Türk Tarih Kurumu Basımevi, 1988, vol. 1, pp. 247, 335-337; vol. 2, pp. 20, 117.

6 Selânikî Mustafa Efendi, Târih-i Selânikî, prepared by Mehmet İpşirli¸ Ankara: Türk Tarih Kurumu, 1999, vol. 2, pp. 614-615.

7 Birol Çetin, Osmanlı İmparatorluğu’nda Barut Sanayi 1700-1900, Ankara: Kültür Bakanlığı, 2001, pp. 20-21; Eyice, “Baruthâne”, vol. 5, p. 95; Refik, 10. Asr-ı Hicrîde İstanbul, p. 159; Ágoston, Barut, Top ve Tüfek, p. 175.

8 Evliya Çelebi, Seyâhatnâme, vol. 1, p. 483.

9 Münir Aktepe, “Kâğıdhaneye Dâir Bâzı Bilgiler”, İsmail Hakkı Uzunçarşılı’ya Armağan, Ankara: Türk Tarih Kurumu, 1988, p. 339.

10 Muzaffer Erdoğan, “Arşiv Vesikalarına Göre İstanbul Baruthâneleri”, İstanbul Enstitüsü Dergisi, 1956, vol. 2, p. 120.

11 İbrahim Sezgin, “Osmanlı İmparatorluğu’ndaki Baruthâneler ve Barut İmalatı”, Türkler, ed. Hasan Celal Güzelet. al., Ankara: Yeni Türkiye Yayınları, 2002, vol. 10, p. 145.

12 İbrahim Sezgin, “Osmanlı İmparatorluğu’ndaki Baruthâneler ve Barut İmalatı”, Türkler, ed. Hasan Celal Güzel et.al., Ankara: Yeni Türkiye Yayınları, 2002, vol. 10, p. 145.

13 It is argued that this factory was established in 1089/1678. Uzunçarşılı also takes 1089 as the date of establishment. See: Defterdar Sarı Mehmed Pasha, Zübde-i Vekayiât, prepared by: Abdülkadir Özcan, Ankara: Türk Tarih Kurumu, 1995, p. 647, footnote number 38; İsmail Hakkı Uzunçarşılı, Osmanlı Tarihi, Ankara: Türk Tarih Kurumu, 1988, vol. 4/2, p. 579.

14 Uzunçarşılı, Osmanlı Tarihi, vol. 4/2, p. 579.

15 Defterdar, Zübde-i Vekayiât, pp. 647-648; Mehmed Raşid Efendi, Târih, vol. 2, Istanbul: Matbaa-i Âmire, 1282, pp. 440-442; Vak’a-nüvis Ahmed Lûtfî Efendi Tarihi, prepared by M. Münir Aktepe, Ankara: Türk Tarih Kurumu, 1989, vol. 11, p. 31; Erdoğan, “Arşiv Vesikalarına Göre İstanbul Baruthâneleri”, p. 121; Eyice, “Baruthâne”, V, 95.

16 Defterdar, Zübde-i Vekayiât, p. 648.

17 Mehmed Raşid Efendi, Târih, vol. 3, p. 232.

18 Erdoğan, “Arşiv Vesikalarına Göre İstanbul Baruthâneleri”, pp. 124-125.

19 BOA, D.BŞM.BRİ, no. 18303.

20 BOA, C.AS., no. 38144.

21 BOA, C.AS., no. 47368, 22 Receb 1199/31 declared in May 1785.

22 BOA, D.BŞM.BRİ.DES, IV/126-A.

23 BOA, C.AS., nr. 19849; BOA, HH, no. 13246.

24 Mahmud Râif Efendi ve Nizâm-ı Cedîd’e Dâir Eseri, prepared by Kemal Beydilli and İlhan Şahin, Ankara: Türk Tarih Kurumu, 2001, pp. 47, 68.

25 Eyice, “Baruthâne”, V95.

26 BOA, HH, no. 15443.

27 BOA, C.AS., no. 48260, memorandum dated13 Muharram 1199/ 26 November 1783.

28 Zafer Gölen, Osmanlı Devleti’nde Baruthâne-i Âmire (XVIII. Yüzyıl), Ankara: Türk Tarih Kurumu, 2006, pp. 220-222, 282.

29 POA, HH, no. 28887; 28884.

30 POA, C.AS., no. 32900, Sultan’s edict dated 12 Rabi al-Awwal 1251/8 July 1835 .

31 Mübahat S. Kütükoğlu, “Baruthâne-i Âmire”, DİA, vol. 5, p. 97.

32 Milliyet, 02.06.1953, p. 3.

33 Milliyet, 26.04.1955, p. 7; 16.09.1957, p. 1.

34 Milliyet, 28.07.1972, p. 6.

35 Milliyet, 28.02.1993, p. 16; Serpil Gülbek, “Bakırköy’ün Baruthanesi”, Antik ve Dekor, 1993, no. 19, pp. 152-153.

36 Eyice, “Baruthâne”, vol. 5, p. 95. Also see: Gülbek, “Bakırköy’ün Baruthanesi”, pp. 152-153.

37 Ahmed Efendi, Rûznâme (III. Selim’in Sırkâtibi Ahmed Efendi Tarafından Tutulan Rûznâme), Prepared by V. Sema Arıkan, Ankara: Türk Tarih Kurumu, 1993, pp. 165, 169, 178, 196, 232-233, 386.

38 Mahmud Râif Efendi ve Nizâm-ı Cedîd’e Dâir Eseri, pp. 47-48, 68.

39 POA, C.AS., no. 16334.

40 BOA, C.AS., no. 11555.

41 Mahmud Râif Efendi ve Nizâm-ı Cedîd’e Dâir Eseri, pp. 48, 69.

42 POA, MAD., no. 18679, p. 1; MAD., no. 8939, p. 92; MAD., no 8941, pp. 3, 14.

43 Erdoğan, “Arşiv Vesikalarına Göre İstanbul Baruthâneleri”, pp. 133-136.

44 POA, C.İK., no. 2188.

45 POA, C.ML., no. 11924.

46 Eyice, “Baruthâne”, DİA; vol. 5, 96; Erdoğan, “Arşiv Vesikalarına Göre İstanbul Baruthâneleri”, p. 138.

47 Salih Sütlan, “Tarihi Baruthane ve Su Bendi İlgi Bekliyor”, Kent Yaşam, 31.01.2011; Arif Sapmaz - Salih Sütlan, “Bakanlık Su Bendine Sahip Çıktı”, Kent Yaşam, 12.04.2011.